Guide pulleys are crucial elements in mechanical systems, ensuring smooth operation by guiding cables, ropes, or belts. They enhance efficiency, distribute loads evenly, and reduce wear, making them indispensable in various industries.

1.1 Definition and Basic Function

A guide pulley is a mechanical component designed to direct the movement of cables, ropes, or belts within a system. Its primary function is to prevent misalignment and ensure smooth operation, thereby enhancing efficiency and reducing wear on moving parts. Properly installed guide pulleys are essential for maintaining the longevity and performance of machinery.

1.2 Historical Development and Evolution

Guide pulleys have evolved from simple, hand-carved blocks to precision-engineered components. Early systems utilized wooden rollers, while modern designs incorporate advanced materials like nylon and steel. The Industrial Revolution introduced standardized manufacturing, enhancing durability and versatility. Today, guide pulleys feature self-lubricating bearings and smart integration, reflecting continuous innovation to meet industrial demands.

Types of Guide Pulleys

Guide pulleys are categorized into fixed, movable, and self-aligning types. Each design offers unique functionality, ensuring optimal performance in various applications by catering to specific mechanical requirements.

2.1 Fixed Guide Pulleys

Fixed guide pulleys are stationary components that provide a consistent path for cables, ropes, or belts. They are typically mounted in permanent positions, offering minimal movement and ensuring precise alignment; These pulleys are ideal for applications requiring stability and are often used in industrial machinery and elevator systems to maintain consistent tension and direction.

2.2 Movable Guide Pulleys

Movable guide pulleys are designed to adjust position, allowing flexibility in redirecting cables, ropes, or belts. They are often used in applications requiring dynamic alignment, such as material handling systems. These pulleys can be manually or mechanically adjusted, offering versatility in various industrial settings where adaptability and precision are essential for optimal performance and efficiency.

2.3 Self-Aligning Guide Pulleys

Self-aligning guide pulleys automatically correct misalignment, ensuring proper belt or cable tracking. This reduces stress on connected components and minimizes wear. They are ideal for systems requiring consistent tension and are commonly used in industrial machinery and conveyor systems, offering reliable performance with minimal maintenance needs;

Materials and Construction

Guide pulleys are made from durable materials like steel and aluminum for strength and corrosion resistance. Plastics are used for lighter applications. Manufacturing involves casting, machining, and 3D printing, ensuring precision and durability.

3.1 Common Materials Used

Guide pulleys are typically made from high-strength materials such as steel, aluminum, and durable plastics. These materials provide excellent resistance to wear and corrosion. Advanced composites are also used for lightweight applications. The choice of material depends on the intended use, ensuring optimal performance in various environments, from heavy machinery to marine and food processing industries.

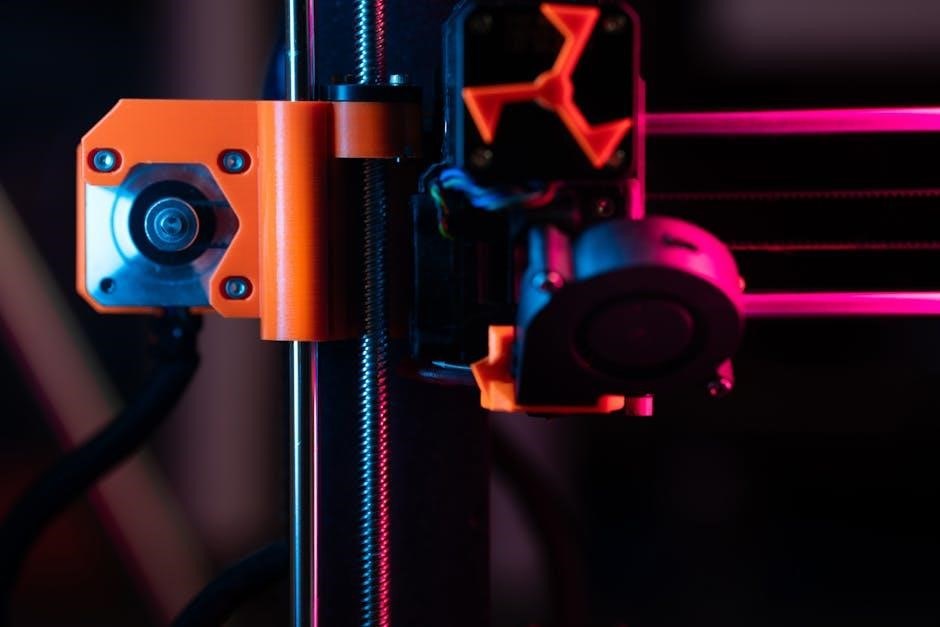

3.2 Manufacturing Processes

Guide pulleys are manufactured using precision techniques such as CNC machining, casting, and forging. Advanced methods like 3D printing are also employed for complex designs. The process ensures high durability and accuracy, with surface treatments applied to enhance resistance to wear and corrosion, meeting specific industry standards for performance and reliability.

Advantages and Benefits

Guide pulleys improve efficiency, reduce wear, and enhance safety. They ensure smooth operation, minimize mechanical stress, and provide consistent performance across various applications, making them indispensable in industrial setups.

4.1 Improved Efficiency

Guide pulleys significantly enhance system efficiency by minimizing friction and ensuring smooth, consistent movement. They optimize performance in mechanical systems, allowing machinery to operate at higher capacities without breakdowns. This leads to increased productivity and reduced downtime, making guide pulleys a vital component in maintaining operational excellence across various industries.

4.2 Reduced Wear and Tear

Guide pulleys minimize wear and tear by evenly distributing loads and aligning cables, ropes, or belts. This reduces friction and prevents misalignment, extending the lifespan of connected components. Durable materials and precise engineering further enhance longevity, lowering maintenance costs and ensuring reliable operation over time.

4.3 Enhanced Safety Features

Guide pulleys incorporate safety features that prevent accidents and protect users. They ensure secure cable or rope guidance, reducing the risk of tangling or snapping. This enhances operational safety, protects equipment from damage, and minimizes hazards in high-stress environments. Advanced designs often include guards or covers to prevent accidental contact with moving parts.

Applications Across Industries

Guide pulleys are essential in industrial machinery, elevator systems, and material handling equipment. They ensure smooth operation, precise alignment, and efficient cable or rope guidance across diverse applications.

5.1 Industrial Machinery

Guide pulleys play a vital role in industrial machinery by ensuring precise alignment and smooth movement of cables, ropes, or belts. They are widely used in heavy-duty applications, including lifting systems, conveyor belts, and material transport. Their durability and ability to handle high loads make them essential for maintaining operational efficiency in demanding industrial environments.

5.2 Elevator Systems

Guide pulleys are essential in elevator systems for ensuring smooth and consistent cable movement. They maintain proper alignment, reducing wear and tear on components. By providing a stable path for cables, they enhance the reliability and safety of elevator operations, ensuring efficient and precise vertical transportation in high-rise buildings and structures.

5.3 Material Handling Equipment

Guide pulleys play a vital role in material handling systems, ensuring smooth movement of goods along conveyors or lifts. They maintain proper alignment and tension, preventing misalignment that could damage equipment or disrupt operations. By guiding cables and belts precisely, they enhance efficiency, reduce wear, and improve safety, enabling reliable and continuous material transportation in industrial settings.

Maintenance and Inspection

Regular lubrication and thorough inspections are essential for guide pulleys to ensure smooth operation. Cleaning and replacing worn parts prevent friction and extend lifespan, maintaining efficiency and safety.

6.1 Regular Lubrication Practices

Regular lubrication is essential to reduce friction and wear on guide pulleys. Use high-quality, silicone-based lubricants or grease, applying them at intervals specified by the manufacturer. Ensure the pulley is clean before application to prevent contamination. Over-lubrication can attract dirt, so apply judiciously. Manual or automatic lubrication systems can be employed for consistent maintenance and optimal performance.

6.2 Inspection Techniques

Inspect guide pulleys regularly for signs of wear, misalignment, or damage. Visually check for cracks, scoring, or excessive rust. Measure pulley diameters to ensure they are within specified tolerances. Assess belt or cable alignment and tension. Use precision tools to verify surface flatness and proper seating. Document findings for maintenance records and schedule repairs or replacements as needed to maintain optimal functionality.

6.3 Replacement Guidelines

Replace guide pulleys when wear exceeds manufacturer limits or if damage is detected. Use compatible replacements to ensure system integrity. Follow installation instructions precisely, ensuring proper alignment and tension. Apply lubrication as specified. Replace worn or damaged accessories simultaneously. Document the replacement for maintenance records, ensuring compliance with safety and performance standards to maintain operational reliability and efficiency over time. Always refer to the manufacturer’s guidelines for specific recommendations tailored to your equipment needs, ensuring optimal performance and longevity of the system. Proper replacement practices prevent downtime and extend the lifespan of the machinery, safeguarding against unexpected failures and ensuring continuous productivity. Regular updates and adherence to maintenance schedules are crucial for sustaining peak functionality. Additionally, consider environmental factors and operational conditions when selecting replacement parts to ensure they meet the required specifications and can withstand the demands of the application. By following these guidelines, you can ensure a smooth transition and maintain the overall health of your mechanical systems. This systematic approach minimizes risks and maximizes efficiency, making it a cornerstone of effective maintenance routines.

Selection Criteria

Selecting the right guide pulley involves evaluating load capacity, speed, and environmental factors. Ensure compatibility with existing systems and choose materials suited for the application’s demands, optimizing performance and longevity while adhering to safety standards and operational efficiency requirements.

7.1 Load Capacity Considerations

Load capacity is a critical factor in selecting guide pulleys. Ensure the pulley can handle the maximum weight and stress of the system. Exceeding the load capacity can lead to premature wear or failure. Always consult the manufacturer’s specifications to match the pulley’s capacity with the application’s demands, ensuring safe and efficient operation.

7.2 Speed and Environmental Factors

Speed and environmental factors significantly influence guide pulley performance. Higher operational speeds require pulleys with enhanced durability and smooth surfaces to minimize friction. Environmental conditions, such as extreme temperatures or corrosive substances, necessitate specialized materials or coatings. Ensuring compatibility with these elements is crucial for optimal functionality and longevity in various applications. Ignoring these factors can lead to premature wear or failure, emphasizing the importance of careful selection.

7.3 Compatibility with Existing Systems

Compatibility with existing systems is crucial when selecting guide pulleys. They must integrate seamlessly with current machinery and infrastructure to ensure smooth operation. Proper sizing, mounting styles, and material selection are key factors to avoid installation issues. Ensuring compatibility prevents operational disruptions and maximizes efficiency, making it a critical consideration in the selection process for guide pulleys across industries.

Future Trends and Innovations

Future trends in guide pulleys include advanced materials, smart technologies, and energy-efficient designs. These innovations aim to enhance durability, reduce maintenance, and optimize performance in various applications.

8.1 Advanced Material Developments

Research into advanced materials, such as high-performance polymers and lightweight composites, is revolutionizing guide pulleys. These materials offer improved durability, thermal resistance, and reduced weight, enabling pulleys to perform better in extreme conditions. Innovations like ceramic coatings further enhance wear resistance, while self-lubricating materials reduce friction and energy consumption, making systems more efficient and sustainable.

8.2 Integration with Smart Technologies

Guide pulleys are increasingly integrated with smart technologies, such as IoT sensors and AI-driven systems. These innovations enable real-time monitoring of pulley performance, predictive maintenance, and optimized energy use. Smart sensors detect wear and tear, while AI algorithms predict potential failures, ensuring uninterrupted operations. This integration enhances efficiency, reduces downtime, and aligns with Industry 4.0 goals for smarter, data-driven machinery.

8.3 Energy Efficiency Improvements

Advancements in guide pulley design focus on minimizing energy consumption. Low-friction coatings and optimized grooves reduce wear and heat generation. Lightweight materials, such as advanced polymers, decrease rotational inertia, lowering energy demands. These innovations not only enhance performance but also contribute to environmental sustainability by reducing carbon footprints, making them a cost-effective solution for modern industries.

Guide pulleys play a vital role in enhancing mechanical systems’ efficiency, safety, and reliability. Their evolution, diverse applications, and continuous improvement highlight their importance across industries. As technology advances, guide pulleys will continue to adapt, offering smarter, energy-efficient solutions that drive innovation and sustainability, ensuring their relevance in future industrial and technological landscapes.