Installation and Setup

The installation and setup involve unpacking and placing the dispenser on a flat surface‚ ensuring proper alignment and connection to a power source. Always inspect for damage before use and refer to the manual for specific configuration guidelines.

1.1. Installation Steps

The installation of the Ecolab chemical dispenser involves several key steps. First‚ carefully unpack the dispenser and ensure all components are included and undamaged. Place the unit on a flat‚ stable surface‚ ensuring proper alignment and accessibility. Next‚ connect the dispenser to a power source‚ following the voltage specifications outlined in the manual. Ensure the dispenser is securely fastened to prevent movement during operation. Before initial use‚ inspect all connections and components for any signs of damage or wear. Refer to the manual for specific installation requirements‚ such as mounting brackets or additional hardware. Finally‚ test the dispenser to ensure it functions correctly before proceeding to setup and configuration.

1.2. Initial Setup and Configuration

After installation‚ configure the dispenser according to the manual’s guidelines. Set the desired chemical concentration levels and dispensing volume using the control panel. Calibrate the system to ensure accurate measurements‚ following the calibration procedure outlined in the manual. Program the dispenser with specific dosing schedules or cycles if required. Ensure all safety features‚ such as automatic shutoff‚ are enabled. Test the dispenser by running a few cycles to verify proper operation. Refer to the manual for troubleshooting any initial issues. Proper setup ensures safe and efficient operation‚ aligning with the dispenser’s intended use and performance standards.

Operation and Programming

Operate the dispenser by following programmed settings for precise chemical distribution. Adjust dosing cycles and monitor performance through digital interfaces for optimal efficiency and accuracy.

2.1. Programming Instructions

Programming the Ecolab dispenser involves setting specific dosing cycles and chemical concentrations. Use the digital interface to input desired parameters‚ ensuring accurate and efficient dispensing.

Access the programming menu by navigating through the control panel. Set the dispensing volume‚ frequency‚ and duration according to your requirements.

Once programmed‚ the dispenser will automatically adjust to maintain consistent chemical distribution. Regularly review and update settings to optimize performance and adapt to changing needs.

2.2. Daily Operation Guidelines

Ensure the dispenser is turned on and properly connected to a power source. Check chemical levels daily and refill as needed to maintain consistent dispensing performance.

Use the digital interface to monitor the dispenser’s status and adjust settings if required. Regularly inspect the dispenser for any blockages or wear and tear.

For touch-free models‚ ensure the sensor is clean to avoid dispensing issues. Follow the recommended cleaning schedule to prevent bacterial growth and maintain hygiene standards.

Maintenance and Troubleshooting

Perform routine checks for blockages and clean the dispenser regularly to ensure smooth operation. Refer to the manual for troubleshooting guidelines and maintenance schedules.

3.1. Routine Maintenance Requirements

Regular maintenance ensures optimal performance of the Ecolab dispenser. Clean the dispenser surfaces and nozzles daily to prevent chemical residue buildup. Inspect tubes and connections for blockages or damage. Replace worn-out seals or O-rings as needed. Check the battery levels if applicable and ensure proper power supply. Refer to the manual for specific maintenance schedules and recommended cleaning agents. Perform a system flush every 30 days or as specified to maintain hygiene. Always follow safety guidelines when handling chemicals or electrical components during maintenance; Keep a log of maintenance activities to track service history and ensure compliance with operational standards.

3.2. Troubleshooting Common Issues

Identify and resolve common issues promptly to ensure dispenser functionality. Check for clogged nozzles‚ which may require cleaning or replacement. If the dispenser fails to activate‚ verify power supply and ensure proper installation. Low chemical levels or empty tanks should be addressed by refilling according to the manual. For inconsistent dispensing‚ inspect tubing for blockages or kinks. If the system displays error codes‚ consult the troubleshooting section in the manual for specific solutions. Regularly cleaning the push bar and sensors can prevent operational issues. Always wear PPE when handling chemicals or performing repairs. Refer to the maintenance log to identify recurring problems and schedule professional service if needed.

Safety Guidelines

Adhere to safety guidelines by wearing PPE‚ including safety glasses and gloves when handling chemicals. Ensure proper ventilation and follow the manual’s safety protocols to prevent accidents.

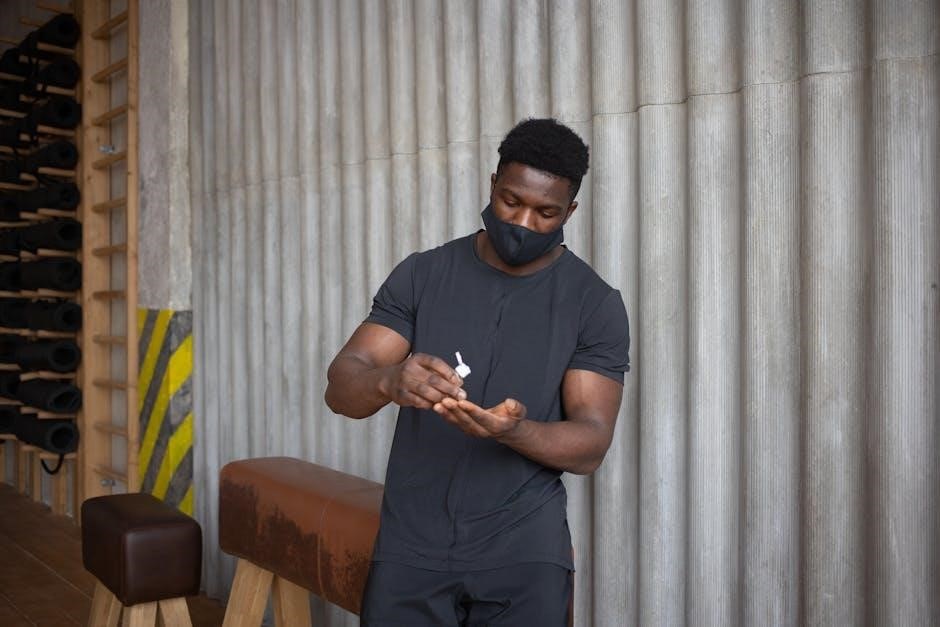

4.1. Personal Protective Equipment (PPE)

Always wear appropriate PPE‚ including safety glasses and gloves‚ when handling chemicals or operating the dispenser. This protects against potential splashes or spills. Ensure PPE meets workplace safety standards and is worn correctly. Lab coats and closed-toe shoes are also recommended for additional protection. Regularly inspect PPE for damage or wear and replace as needed. Proper use of PPE minimizes exposure risks and ensures safe operation. Always follow the manual’s guidelines for specific PPE requirements based on the chemicals being dispensed. Remember to wash hands thoroughly after removing gloves. Compliance with PPE protocols is essential for maintaining a safe working environment and preventing accidents.

4.2. Safe Handling of Chemicals

Always handle chemicals with care to avoid exposure and ensure safe operation. Read and follow the Safety Data Sheet (SDS) for each chemical. Wear appropriate PPE‚ including gloves and safety glasses‚ when handling or refilling chemicals. Ensure the area is well-ventilated to prevent inhalation of fumes. Store chemicals in their original containers‚ away from incompatible substances‚ and in designated storage areas. Never mix chemicals unless explicitly instructed by the manufacturer. In case of spills‚ contain the spill immediately‚ neutralize if possible‚ and clean up thoroughly using recommended materials. Dispose of waste according to local regulations and environmental guidelines. Proper chemical handling prevents accidents and ensures a safe working environment. Always refer to the manual for specific instructions related to the dispenser’s chemical requirements.

Technological Advancements

Recent advancements include digital monitoring systems for precise chemical control and personalized dispensing options. Touch-free dispensers enhance hygiene‚ while mobile integration enables real-time tracking and efficient management.

5.1. Digital Monitoring and Personalized Dispensing

Digital monitoring systems enable real-time tracking of chemical usage‚ ensuring precise control over dispensing levels. Personalized dispensing options allow customization of dosing based on specific requirements‚ optimizing efficiency. Advanced sensors detect product levels‚ alerting users to replenish supplies proactively. Integration with facility management systems streamlines operations‚ reducing waste and improving accuracy. These technologies enhance compliance with safety standards while minimizing manual intervention‚ ensuring consistent and reliable performance. Digital interfaces provide clear data visualization‚ facilitating informed decision-making. This innovation aligns with modern demands for precision‚ sustainability‚ and user-centric design in chemical dispensing solutions.

5.2. Touch-Free Dispensing Systems

Touch-free dispensing systems offer enhanced hygiene and convenience by eliminating the need for physical contact. These systems utilize infrared sensors to detect user presence‚ dispensing the desired amount of product automatically. They are compatible with various liquids‚ gels‚ and foams‚ allowing for easy product changes without requiring different dispensers. This versatility reduces inventory complexity and streamlines purchasing. Ecolab’s touch-free systems are designed for durability and ease of use‚ integrating seamlessly into high-traffic environments. They minimize the risk of cross-contamination‚ making them ideal for healthcare and public facilities. Additionally‚ these systems often feature low-battery indicators and adjustable dispensing amounts‚ ensuring consistent performance and user satisfaction. Their hands-free operation promotes accessibility and adheres to modern hygiene standards‚ making them a practical choice for diverse settings.