Metric pipe thread charts provide standardized specifications for thread dimensions, ensuring compatibility and safety in plumbing and engineering applications. They detail pitch, diameter, and taper measurements, essential for accurate fittings and connections. These charts are crucial for identifying thread types, such as coarse or fine pitch, and ensuring compliance with international standards like ISO and DIN. By referencing these charts, professionals can select the correct thread sizes for their projects, guaranteeing reliable seals and structural integrity.

Definition and Importance of Metric Pipe Threads

Metric pipe threads are standardized screw threads used globally for connecting pipes and fittings. Defined by ISO and DIN standards, they specify thread diameter, pitch, and shape in millimeters. The thread pitch, measured as the distance between threads, and the nominal diameter ensure compatibility across systems. Metric threads are vital for ensuring leak-free connections, structural integrity, and proper fluid flow in industrial, plumbing, and mechanical applications. Their standardized nature facilitates global interoperability, making them essential for modern engineering and manufacturing. Accurate thread specifications prevent errors, enhance safety, and reduce costs, highlighting their critical role in maintaining system reliability and efficiency.

Understanding Metric Thread Specifications

Metric thread specifications define standard dimensions for screw threads, ensuring compatibility and accuracy. They include nominal diameter, pitch, and thread form, critical for proper connections and safety in applications.

Nominal Diameter and Pitch Measurements

Nominal diameter and pitch are fundamental in metric thread specifications. The nominal diameter is the major diameter of the thread, measured in millimeters, while the pitch is the distance between consecutive threads. For example, in M10x1.5, the nominal diameter is 10mm, and the pitch is 1.5mm. These measurements ensure compatibility and proper fitment in piping systems. The pitch can vary, with coarse threads having larger pitches for quicker assembly and fine threads offering tighter seals. Accurate measurement of these dimensions is critical for selecting the correct fittings and ensuring leak-free connections in various applications.

Interpreting Metric Thread Callouts (e.g., M10x1.5)

Metric thread callouts, such as M10x1.5, provide essential information for thread identification. The “M” denotes a metric thread, while the number following it indicates the nominal diameter in millimeters. In this example, “10” signifies a 10mm diameter. The “1.5” represents the thread pitch, the distance between consecutive threads in millimeters. This standardized notation ensures clarity and consistency in specifications. Understanding these callouts is crucial for selecting the correct fittings and tools, ensuring proper assembly and sealing in piping systems. Referencing metric pipe thread charts helps verify these measurements and guarantees compliance with international standards, making it easier to identify and source compatible components efficiently.

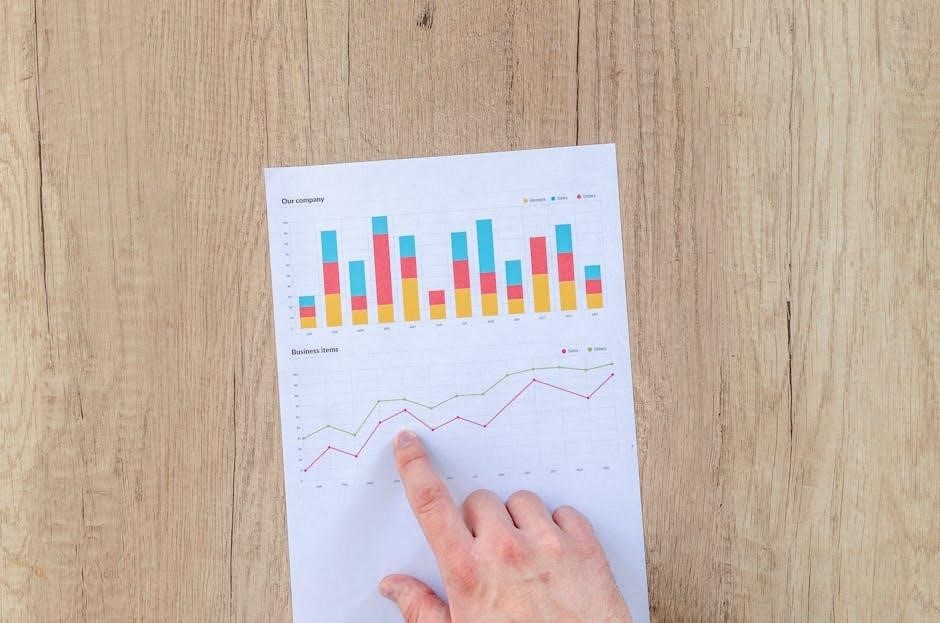

Key Elements of a Metric Pipe Thread Chart

Metric pipe thread charts outline thread dimensions, pitches, and tolerances, ensuring precise fitting and compatibility. They include nominal diameters, pitch measurements, and thread forms for various applications, aiding in accurate selections and installations.

Thread Pitch and Class Tolerances

Thread pitch refers to the distance between consecutive threads, measured in millimeters for metric systems. Common pitches include 1.0, 1.5, and 2.0 mm. Class tolerances define the acceptable deviations in thread dimensions, ensuring proper fitment and functionality. These tolerances are categorized into classes like 6g (general use) and 4g (closer fit). Understanding pitch and tolerance classes is critical for selecting the right thread size, as deviations can affect sealing and mechanical integrity. Proper adherence to these specifications ensures leak-free connections and optimal performance in piping systems. Referencing a metric thread chart helps in identifying the correct pitch and tolerance for specific applications. Accurate measurements using calipers are essential for verification.

Major and Minor Diameter Dimensions

The major diameter is the largest diameter of the thread, while the minor diameter is the smallest, measured at the base of the thread. These dimensions are critical for ensuring proper thread engagement and sealing. For metric threads, the major diameter is typically specified in millimeters, with the minor diameter calculated based on the pitch and thread angle. Accurate measurement of these dimensions is essential for thread identification and compatibility. Using calipers, professionals can measure these diameters to verify compliance with standards. Proper alignment of major and minor diameters ensures secure connections and prevents leakage in piping systems. These measurements are standardized in metric thread charts for reference.

How to Read a Metric Thread Chart

To read a metric thread chart, identify the thread type, nominal diameter, and pitch. Determine if the thread is parallel or tapered, then use calipers for precise measurements to ensure accuracy.

Identifying Parallel and Tapered Threads

Parallel threads have consistent diameter and spacing, ideal for applications requiring a smooth, even connection. Tapered threads, like NPT, gradually decrease in diameter, creating a tight seal when engaged; To identify, measure the thread’s start and end diameters. Parallel threads maintain uniformity, while tapered threads show a visible angle. Referencing a metric pipe thread chart helps distinguish between the two, ensuring correct component selection and proper installation. Calipers and thread gauges are essential tools for accurate measurement and identification, preventing assembly errors and ensuring system integrity.

Using Calipers for Accurate Measurements

Calipers are indispensable for precise measurement of metric pipe threads. They enable accurate determination of major and minor diameters, crucial for identifying thread sizes. Open the calipers to measure the outer diameter of male threads or the inner diameter of female threads. Ensure the tips are aligned perpendicular to the thread axis for precise readings. Digital calipers offer enhanced accuracy and ease of use. By referencing the measurements against a metric pipe thread chart, users can confirm thread specifications, ensuring compatibility and correct installation. This method is essential for maintaining quality and safety in plumbing and engineering applications.

Common Metric Thread Types and Applications

Metric threads include coarse and fine pitch types, with standard sizes like M10 and M12. Coarse threads are commonly used in general engineering, while fine threads suit precision applications.

Coarse vs. Fine Pitch Threads

Coarse pitch threads, such as M10x1.5, offer a larger pitch, making them easier to assemble and suitable for general engineering applications. Fine pitch threads, like M10x1.25, have a smaller pitch, providing higher strength and resistance to stripping. Coarse threads are ideal for quick assembly and are commonly used in plumbing, while fine threads are preferred in precision machinery and automotive applications. The choice between them depends on the required strength, resistance to vibration, and ease of use, with charts providing detailed specifications to guide selection.

Standard Metric Thread Sizes (e.g., M10, M12)

Standard metric thread sizes, such as M10 and M12, are widely used in engineering and manufacturing. These sizes are defined by their nominal diameters and pitches, ensuring compatibility across applications. M10 threads, with a 10mm diameter, are commonly used in lightweight applications, while M12 threads, with a 12mm diameter, offer greater strength and are often found in machinery and automotive components. These standard sizes are detailed in metric thread charts, providing essential dimensions for major and minor diameters, thread pitch, and class tolerances. Adherence to these standards ensures seamless integration and reliability in various industrial and mechanical systems.

Tools and Resources for Thread Identification

Thread gauges and calipers are essential tools for precise measurements. PDF charts and online references provide detailed thread specifications, ensuring accurate identification and compatibility in metric pipe applications.

Thread Gauges and Measurement Tools

Thread gauges and measurement tools are essential for accurately identifying and verifying metric pipe thread dimensions. Calipers are widely used to measure the outer diameter of male threads and the inner diameter of female threads, ensuring precise measurements in millimeters. Pitch gauges are another critical tool, helping to determine the thread pitch by measuring the distance between adjacent threads. These tools are particularly important for ensuring compliance with ISO and DIN standards. By using these resources, professionals can confirm that threads meet specified tolerances, such as those outlined in metric pipe thread charts. Accurate measurements are crucial for maintaining safety and efficiency in engineering and plumbing applications.

PDF Charts and Online References

Metric pipe thread charts are widely available in PDF format, offering detailed specifications for various thread sizes and types. These documents typically include tables with nominal diameters, pitch measurements, and thread angles, ensuring precise identification and application. Online references, such as ISO and DIN standards, provide comprehensive guides for metric threads, including coarse and fine pitch variations. Websites like engineering portals and manufacturer resources often host these charts, making them easily accessible for professionals. By referencing these PDFs, users can quickly identify thread specifications, such as M10x1.5 or M12x1.75, and ensure compliance with international standards. They are invaluable tools for engineers and technicians working with metric pipe threads.